It would be great that car enthusiasts know how to compress brake calipers to fix their pads themselves when they need to get them changed.

Suppose you are reading the post to understand how to compress brake calipers. In that case, there are chances that you may be having issues with the compression of brake calipers.

As much as one would advise that matters of breaks be handed to professionals, it is equally essential to know how to compress brake calipers.

A Brief Review of Cars Braking System

But before going into detail about how to compress the brake caliper, let us talk about the car braking system. Our cars are moving metal that could dash into anything that comes their part without a break.

A car braking system is a series of arrangements designed to convert the vehicle’s kinetic energy through friction into heat energy to bring the car or brake from a top speed safely.

They work together to allow us to drive cars safely on our roads, in the cities, when we engage the brake pedal. There are various braking systems, but the system we are basing our focus on is the hydraulic brake system.

There are eleven essential brake components in a modern car. The components and their purposes are;

01. The Brake Pedal

The brake pedal extension of the brake system allows the operator or driver to control the entire brake system.

They are usually located where it is accessible by foot. It is operated by simply stepping on the pedal as desired.

02. Master Brake Cylinder

The master cylinder acts to push hydraulics through the brake lines after the pedals are stepped on.

The harder we step on the pedals, the stronger the effect as more fluid is forced through the tube to cause other components to act and bring the car under control.

For some vehicles, it is a single central cylinder that serves fluid pressure to all wheels. Still, in modern cars, the cylinder is divided into twos or fours for safety reasons.

In that case, the cylinders act separately and independently when one fails.

03. Brake Disc

The disc rotates alongside the wheel as the car moves. The purpose is to give the brake pad and caliper a gripping surface, creating friction between the brake pad and the disc.

Causing the motion on the wheels to die away slowly.

04. Brake Drum

The brake drum act almost in a similar way as the brake disc. However, they have the same purpose. A car can either possess the disc system or drum system or the most common system combined.

The rear wheels often come in the drum in the integrated system, while the front wheels come with the disc. The brake drum rotates as the wheels.

05. Brake Pad

Brake pads are used for the disc system, and their purpose is to hold firm the rotating disc when acted upon.

06. Brake Calipers

Brake calipers act by bringing the clamping force, which pushes the brake pad into the disc.

07. Brake Shoe

The brake shoe is just another version of a brake pad, and its purpose is to force motions to seize from the drums.

08. Brake Booster

The booster is part of the brake system whose purpose is to amplify the pressure using a vacuum after the brake is stepped on. It is also called a vacuum servo.

09. Brake lines

Brake lines serve the vessels through which the hydraulic fluid is compressed as they travel from the liquid (hydraulic) tanks to the wheels, where they cause actions on other components.

10. Wheel Speed Sensor

Not all cars come with a speed sensor, but most modern cars do. The speed sensor is a sensitive device that feeds data of the speed at which the vehicle moves to a computer.

11. ABS Module

ABS stands for Anti-Braking System. The ABS module is a computer that receives data from speed sensors.

It acts according to the manufacturer’s instructions causing the car to be brought under safe control quickly than the drive would initiate.

Only a few vehicles come with these components, especially in modern vehicles.

How does the Brake Caliper Piston Work?

A piston is like an arm whose actions force another part or component to react. The brake caliper piston is an essential part of the brake system.

When a driver steps on the brake pedal, it forces hydraulics out from the master cylinder through the brake lines. Pressure builds up in the bar, which pushes against the caliper pistons.

This then forces the brake calipers to move the brake pad between the discs causing it to slow its motion by friction.

Reasons why Brake Caliper Piston Won’t Compress

A brake caliper may not compress for some number of reasons, and some of the most common issues or reasons they may not compress are;

01. Corrosion

when vehicles are made to remain motionless for a long time, rust due to the hydraulic substance quickly develops on the caliper, and this will cause it not to compress.

02. Deformed piston

due to the constant application of breaks, the piston seals are gradually deformed. This will go on until the piston fails to appropriately fit the seal, causing the piston to get stuck.

This leads to partial compression and causes the brake caliper not to compress.

03. Wear and Tear

this is a most common problem with mechanical components generally.

Caliper bolts consist of the slide, which requires lubrication always, and the plastic boots present to assist in this lubrication.

Changing brake pads get them to wear and causing the brake caliper piston not to compress.

How to Compress Brake Caliper in Easy Way

Before seeing how to brake, You can compress calipers, and there is a need to understand why we have to compress them in the first place.

Unfortunately, while this wear of the brake pad is happening, it leaves the brake caliper hanging out with the piston, causing the brake pads to close in on the disc (rotor) by a few inches.

This will go on if they are not replaced until they start touching the disc. If we must prevent this, new pads are put in place of the wear out ones.

Replacing brake pads can be technical and requires some compression force to put the caliper back into position after replacing a pad.

The compression is done by slowly pushing the pistons in the caliper back into their housing. Before compression, it is necessary to determine the best compression method and tools to use that will cause minor damage or injury.

You can compress brake calipers in different ways. They can be compressed using a c-clamp, channel locks, and caliper piston compression tools.

But there are things you must do before you start to compress, and they are;

- Remove the lid on the hydraulic reservoir to reduce the excessive pressure that will build up when compressing the calipers.

- Have your bleeder valve open.

- Place a source pan beneath to collect the fluid.

Now, having done the above, let’s see how to use these compression methods;

01. How to Compress Brake Caliper with C-Clamp

This method on how to compress brake calipers include;

- Place the c-clamp at a firm position over the caliper and make the end push against the piston. Place the c-clamp over the brake caliper. Let the brake pad in front of the piston and in-between the jaws of the clap.

- Turn the screw gently as you adjust: – wind down the screw on the clamp and make it close to clapping on the brake pad and the caliper.

- Place a wood block between the clamp and the piston: – the clamp jaws may dent a hole into the brake pad, and to avoid this, place a wood block between and tight the clamp hard.

- Screw on the clamp: – Screw or tighten the clamp as they compress, pulling inward the piston.

- Adjust until it is just right to fit the new brake pads onto the caliper:- keep tightening the clamp until the piston adjusts rightly for the new brake pad to sit in.

02. How to Compress Brake Caliper Using Channel Locks

This method is similar to the c- clamp method, only that the tools are operated differently. Now, let’s see how to compress brake calipers using this method.

- Take the caliper off; get the caliper un-tightened, and pull out the bolt.

- Place the brake pad next to the piston; place the brake pad in front of the piston and make it fit just well and adjust the channel, then place channel lock to a position.

- Place your channel locks; put it such that one end of the grip is behind the caliper and the other behind the brake pad, or place such that the caliper and brake pad are placed between the grips.

- Squeeze the channel locks and squeeze the piston back in:- now, slowly but gently compress the piston by squeezing hard on the channel lock until the piston is successfully retracted inward.

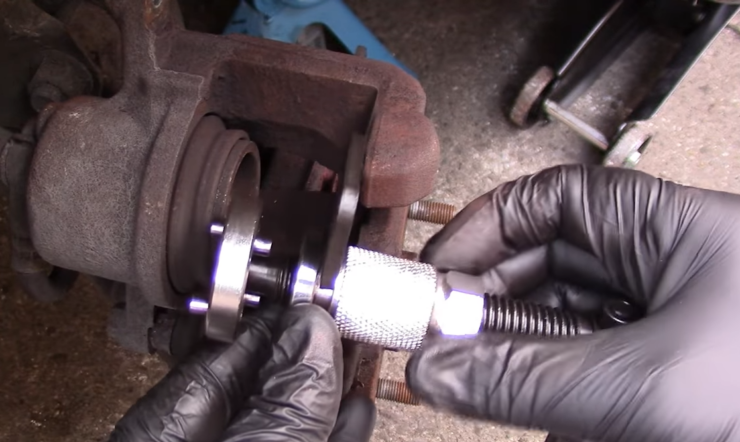

03. How to Compress Brake Caliper with Caliper Piston Compressor Tool

This method on how to compress brake calipers include;

- Take the caliper off; as usual, pull the caliper off from its bolts.

- Place brake pad in front of piston: – place brake pad in front brake caliper and the brake piston.

- Place the caliper compressor inside the caliper: – make sure the caliper compressor is adjusted and the push bar is not hanging out already. Then place the caliper compressor on the side of the caliper, just in front of the brake pad.

- Pump down the compressor tool and have your brake pad in position; now pump while the push bar pulls out to push against the brake pad and cause the brake pad to go against the piston as it retracts.

This ways of compressing brake calipers will make plenty of room for the new brake pad to fit in.

04. How to Push Back Brake Piston Without Tool

This method on how to compress brake calipers include;

- Place a regular screwdriver in the caliper window: – When you place the screwdriver/bar in the brake caliper window, hold firm as you move inward between the openings. Dip the screwdriver to a length where you have an equal balance in the force to pull. And this will cause the brake piston to pull back slightly.

- Pull outwards; after the screwdriver is in, pull moderately but firmly against the brake pad outwardly.

- Place the screwdriver between the brake pad and piston; now, place your screwdriver between your brake pad and brake caliper and find the piston using your screwdriver.

- Push the piston back; having found the piston head, gently but firmly push the piston back in all the way.

Important notes

Every method may have its pros and cons, but some ways offer the best outcome with room for little or no damage at all.

- When using a screwdriver, it places unequal forces on the piston during compression, and that can cause the caliper piston to get stuck after compression.

Also, suppose the caliper piston is made of phenolic material. In that case, the method of using a screwdriver or other bar to ply on it could get it damaged. - Use methods that provide equal pressure against the pad as you make compression against the piston.

- Do not attempt to use the compression methods above on pads equipped with electric sensors.

- When compressing, make sure you have the bleeder valve opened to drain out the old brake fluid. Place a source pan to collect the drains.

Be sure to keep the bleeder valve in an upward direction and don’t turn over the caliper. In contrast, the bleeder valve is open, as doing this can let a gush of air into the brake system and cause the brake not to function correctly. - Use old brake pads when compressing pistons to avoid damages on the new pads. Otherwise, it may cost you more having to replace another pad.

Suppose you choose to use the new one during compression. In that case, you may risk improper fittings of the pad even if damages may not be visible. This may cause improper functioning of the brakes. - After the release of the valve before compression, you will notice a collapse on the brake pedal. Therefore, after the compression and fitting the calipers to position, you have to get the pedals hard again.

You can get them hard with a continuous pumping down on the pedals. Doing this will send the piston back out to push against the pads. If not, your brakes will not function properly and may fail when the car requires an adequate grip to hold back from the collision.

Do’s

- Always release the bleeder valves

- Use old brake pads when compressing pistons

- Pump on the pedals after compression fixing

- Only compress when your brake pads and calipers have not electric sensors

Don’ts

- Do not tilt the caliper when valves are open

- Do not compress using new brake pads

- Please do not use the brakes until they are hard and you’re satisfied the piston has out pushed the pads to the discs (rotor)

- Please do not compress while there electric sensors.

FAQs

1. Why do my brakes squeak?

Your brake squeaks for different reasons. It could be a result of moisture or debris on the disc (rotor).

It can be caused by brake pads that have worn too low or bad disc (rotor) and a host of other causes. So, you have to find out what the reason could be for yours.

2. Can my brakes function without fluid?

No, your brakes cannot function without fluid. Brake fluid is essential for the proper functioning of your vehicle’s hydraulic braking system. It transfers the force from the brake pedal to the brake calipers, allowing your car to slow down or stop. Without brake fluid, your brakes will fail, creating a dangerous situation on the road.

3. Why does my brake feel soft?

Several issues can cause the pedals to feel soft. It could be from a low level of fluid in the fluid tank or a leakage/breakage along the break line and even as a result of air in the brake line.

4. Why do I feel some vibration on my brakes when stopping?

Feeling vibration in your brakes when stopping can be due to several factors. Some common causes include:

- Warped brake rotors: Over time, heat and wear can cause your brake rotors to become uneven or warped, leading to vibrations when the brake pads make contact with the uneven surface.

- Worn brake pads: As brake pads wear down, they can become uneven, glazed, or contaminated with debris, causing vibrations during braking.

- Loose or damaged suspension components: Vibrations during braking may also be a result of loose or damaged suspension components, such as ball joints, tie rods, or wheel bearings. These parts may need inspection and replacement if necessary.

- Uneven tire wear or wheel imbalance: Tires with uneven wear or wheels that are not properly balanced can cause vibrations when braking. Regular tire rotation and wheel balancing can help prevent this issue.

5. How often can one change brake pads?

The frequency at which brake pads need to be changed depends on various factors, including your driving habits, the type of brake pads, and the specific conditions of your vehicle. As a general guideline, brake pads typically last between 30,000 to 70,000 miles. However, some high-performance or softer compound pads may wear out sooner, while others designed for long life may last longer.

It’s essential to pay attention to signs that your brake pads may need replacement, such as squeaking or grinding noises, a decrease in braking performance, or a warning light on your dashboard. Regularly inspecting your brake pads for wear is also a good practice. When the pad material wears down to about 1/8 inch (3 mm) or less, it’s time to replace them.

Verdicts

With all being said, I believe we have given helpful information about the braking system in your car.

Friction generates an incredible amount of heat which could damage parts of the brake system.

If we must overcome this challenge, components directly involved in frictions are made with unique parts and designed to help dissipate heat quickly.

Related Posts:

- How to Compress Caliper Piston – 6 Best Ways to Do It Right

- 3 Easy Ways of How to Remove Exhaust Hangers - Tips…

- Subaru Key Fob Battery Replacement – 3 Simple &…

- 10 Best Brake Pads For Toyota Camry 2024 - For…

- 13 Best Brake Pads For Toyota Corolla 2024 - Ensure…

- 10 Best Brake Pads for Toyota Tacoma 2024 - Enhance…